HOME -> Engineering Services

ATS India offers integrated engineering and manufacturing solutions to the world-wide Industry. We leverage global standards and established principles in the design and development of different production processes. We collaborate and associate with our customers for mutual benefit, to promote learning and to produce highly efficient and quality-driven equipment. We follow-up with each customer with an offer of robust post-sales service, cost effective maintenance, ensure safety standards, quick availability of spares parts, and on-site employees training on new equipment.

From Seat Track Assembly Lines to Engine Assembly Lines (low volume pilot lines, teardown lines, repair and re-assembly lines, off-line systems) to Transmission Line Design and Integration – we provide the entire scope of supply for a worry-free “NEW” or RE-TOOL” installation for the customer.

With over 100 Years of combined experience, ATS India has been delivering variety of Automatic & Semi-Automatic Stations for over the past decade from small to large scale industries.

Some of our Key Projects are:

-Robotic Weld Cell

-Motor Latch Assembly And Test Station

-Manual Weld Station

ATS India offers Custom Engineered Solutions to our customers with various industry back drops like Infrastructure, Rock Drill Bits Manufacturers, Food Industry, etc. The process includes:

Product Study, Cycle Time Study, Process Study, Concept Development, etc.

Some of our Key Projects are:

-Pump-Up station

-Cross Transfer System

-Hard Facing Station

-Trunnion Teardown

-Modular Engine Carts

At ATS, we combine excellent project management skills with design and engineering skills to provide extensive services for Design Engineering Services.

Some of our Key Projects are:

-MIG Weld Cell for Exhaust System

-Aluminum Weld Station – Design & Build

-Rear Axle Assembly Station

-Weld Stations

-Pallet / Product EOAT Assembly Line - Design & Build

-Robotic Engine Machining

-Bolt Torque Station

The design team is well versed in handling and executing projects for various OEMs and Tier 1 suppliers around the globe in the following areas of competency.

-Process Planning & Preliminary Layout Studies

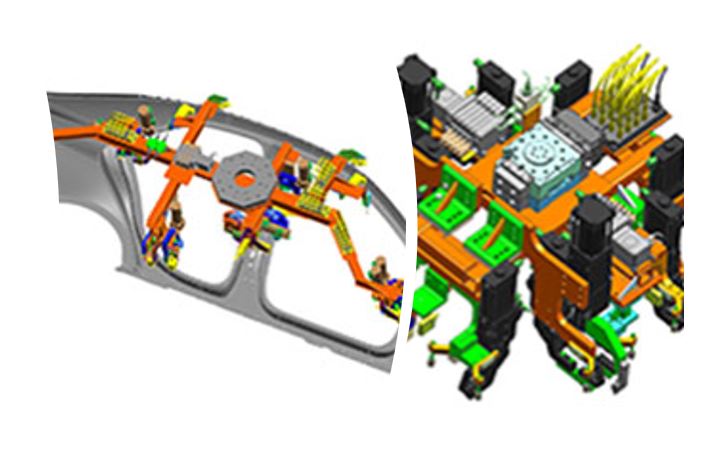

-Fixtures Design & Detail (including Geo and Respot fixtures)

-EOAT Design

-Special Equipment Design

Apart from Turnkey and Custom Engineered Systems and Automation, ATS also provides general engineering services such as:

2D to 3D CAD Conversion – Any format to any format

Drawing Package Preparation – Including Layout Drawings, BOM

Electrical Engineering – Concept Architecture, Electrical Schematics, Fluid Schematics, BOM

Software Development – LabView, Schneider, Allen Bradley, Omron, Siemens

Simulation Services – Robot Simulation, Process Simulation

ATS India's ultimate objective is to deliver its design & manufacturing services to the defence industry. So far ATS India has worked on few proprietary projects for the defence research and development wing used by the law enforcement agents.

Some of our works are:

Know More

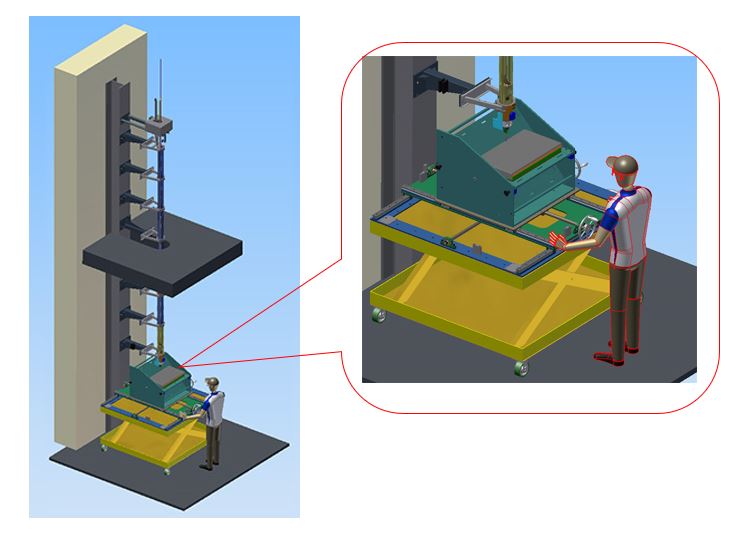

Stab Resist Test Equipment (Bullet Proof Vest Testing): This equipment is used to test the bullet proof vest material using stab test method.

Drop Test Equipment (Backing Material Testing): This equipment is used to test the backing material by "Drop Test" method.

Gun Mounting Stand (Gun Placing and Targeting): This equipment is used to place and position the Gun in Ballistic Testing Line.

Light Screen Stand (Bullet Velocity Measurement): This equipment is used check the speed of the bullet released from gun.

Head Foam / Clay Box Stand (Work Piece Holding): This equipment is used to hold the "Test Specimen" in ballistic testing line.

All the above-mentioned test equipment's are made to the NIJ Standards.